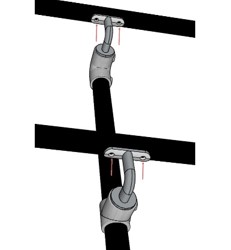

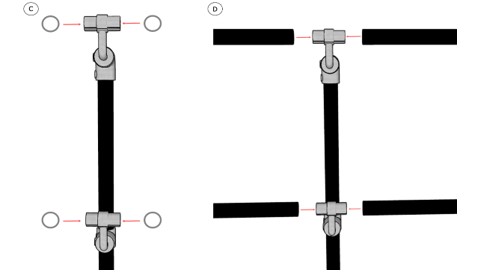

DDA Fixing Types Explained

| Saddle Type | Expanding Type | |

|---|---|---|

| Indicative image |

|

|

| Part Codes | D748/D746 | D747/D745 |

| Handrail tube fixing method |

|

|

| Drill pilot hole then fix with self tapping screws or pop-rivets6 | Cut handrail tube at each upright, add sealing ring either side of clamp and wind in grub screw to expand fitting inside tube | |

| Best suited for | Large and/or commercial installations | Small and/or domestic installations |

| Key benefits | Far fewer handrail tube joins creates the neatest finish | Most simple to install, fittings expand using an allen key. No tube drilling. |

| Less damage to powder coated surface due to fewer cuts | Can be disassembled and reassembled numerous times | |

| Fixing clamps do not have to be powder coated for part M compliance | Attach gradient kits directly to the brackets | |

| Corners and in-line tube joins are the same across both system types. | Corners and in-line tube joins are the same across both system types. | |

| Webshop pages | Shop DDA Saddle clamps | Shop DDA Expanding clamps |

To meet Part K or Part M of the building regulations, handrail should "not become excessively cold or hot to touch" and you should “ensure that the handrail will contrast visually with the background against which it is seen without being highly reflective”. This can be achieved through either Powder Coating or painting the handrail. Very dark colours may get hotter in the summer sun. Find out more information on our Powder Coating service here.

Also ensure the handrail finishes with an End Loop Kit.

Telephone

London: +44(0)20 8254 2626

Sheffield: +44(0)114 312 2250